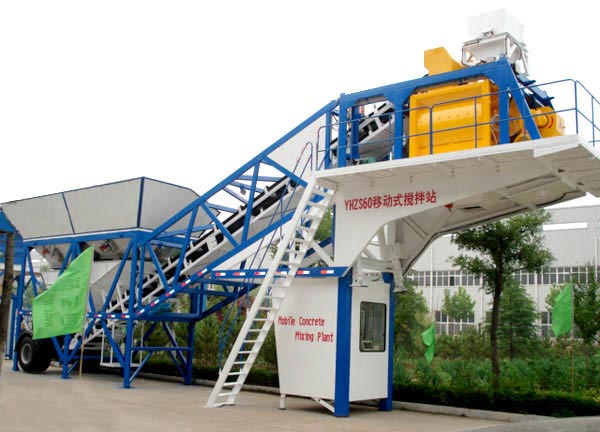

The mobile Concrete batching plant also known as a portable concrete plant is a very productive, reliable and cost effective piece of equipment to produce batches of concrete. Compared with stationary concrete batching plant, It allows the user to batch concrete at most any location then move to another location and batch concrete.Portable Concrete batching plant are the best choice for temporary site projects or even stationary locations where the equipment height is a factor or the required production rate is lower.

Mobile concrete batching plant is specially designed for project with short construction time, long construction line, frequently changing construction site; mobile concrete plant is small in size, so it is also called small concrete batching plant. Our well-sold portable concrete batching plant has the following features: compact in structure, small in space needed, simple in installation, high in automation, it is widely used in the construction of bridge,building, water conservancy project, power and other infrastructure.

Concrete mixer: JS500

Theoretical production capacity (m³/h): 25

Discharging capacity (L): 500

Discharging height: (M): 2.8

Aggregate Bin volume(m³):3.2

Concrete mixer: JS750

Theoretical production capacity (m³/h): 35

Discharging capacity (L): 750

Discharging height: (M): 2.8

Aggregate Bin volume(m³):7.3

Concrete mixer: JS1000

Theoretical production capacity (m³/h): 50

Discharging capacity (L): 1000

Discharging height: (M): 2.8

Aggregate Bin volume(m³):8.3

Concrete mixer: JS1500

Theoretical production capacity (m³/h): 75

Discharging capacity (L): 1500

Discharging height: (M): 3.8

Aggregate Bin volume(m³):12

| Type | YHZS25 | YHZS35 | YHZS50 | YHZS75 | |

|---|---|---|---|---|---|

| Theoretical production capacity(m³/h) | 25 | 35 | 50 | 75 | |

| Concrete mixer | Type | JS500 | JS750 | JS1000 | JS1500 |

| Power(KW) | 24.75 | 38.6 | 51 | 65.5 | |

| Discharging capacity(L) | 500 | 750 | 1000 | 1500 | |

| Aggregate size(Pebble/Macadam)(mm) | 80/60 | 80/60 | 80/60 | 80/60 | |

| Aggregate Bin volume(m³) | 3.2 | 7.3 | 8.3 | 12 | |

| Weighing Accuracy | Aggregate (KG) | ±2% | ±2% | ±2% | ±2% |

| Cement(KG) | ±1% | ±1% | ±1% | ±1% | |

| Fly ash(KG) | ±1% | ±1% | |||

| Water (KG) | ±1% | ±1% | ±1% | ±1% | |

| Additive(KG) | ±1% | ±1% | ±1% | ±1% | |

| Total power(KW) | 50Kw | 64Kw | 85Kw | 110KW | |

| Discharging height(M) | 2.8 m | 2.8 m | 2.8 m | 3.8m | |

| Gross weight(T) | 12 | 16 | 20 | 50 | |

| Download | Download | Download | Download | ||

1. Host chassis: cantilevered stirring host chassis, the chassis contains a trailer truck trailer pin, parking legs, the mixer, cement and water admixture measurement are installed on the chassis.

2. Control room: the control room is installed on the bottom of the host chassis, the automatic control system is in it, the control system is the same as stationary concrete batching plant, on the working status, the control room as the the front support point, in the transfer, the control room stored in the bracket, all of its control lines do not need demolition.

3. Aggregate Ingredient Measure: This system is located in the back of the plant, the upper part is the aggregate (sand, stone) storage hopper, storage hopper can be divided into 2 or 4 cells, and set up higher plate to increase the storage capacity, Pneumatic in turn open the door operation, aggregate measurement use a variety of materials accumulated measurement. The bottom is equipped with a walking leg and a working frame leg.

4. Belt Conveyor: The belt conveyor rack is a truss structure that connects the host chassis and the aggregate dosing frame, and equipped with belt rack. The main frame, the belt frame and the batching frame are combined to form the main structure of the whole mobile concrete batching plant.

5. Peripheral components: the cement warehouse and screw conveyor, peripheral components are the whole parts,do not need dismantling whether work or transport time, so they can overall transport and disassembly.

6. Mixing host: adopt JS-type forced concrete mixer, can be quickly and evenly complete the mixing of fluidity and dry concrete.

We are a prominent organization, which is engaged in manufacturing and supplying optimum-grade Mobile Concrete Batching Plant. Our experienced engineers ensure that finest quality components and other material are used in the manufacturing process. It is checked on various parameters to ensure this product to be highly reliable, excellent in operation, energy efficient and flawless..So, we can guarantee that all of our plant and compulsory mixer have superior quality and advanced technology. We have many models of mobile concrete batching plant for sale, such as: YHZS25, YHZS35, YHZS50, YHZS60, YHZS75.

Offering you a complete choice of products which include mobile concrete batching plant, mobile concrete semi batching plant, mobile concrete plant and mobile semi batching plant.

We would like to highlight our mobile Concrete batching plant,concrete mixer and Concrete Truck Mixer with good quality and competitive price.Our products sell well all over the country and exported to the Outer Mongolia, Indonesia,Russian, Philippine,Macedonia,Tanzania, Paraguay,Australia,Saudi,Malaysia,Zambia,Nigeria Cyprus etc and won overseas customer’s trust and good reputation.

Get in touch and we will reply to you as soon as possible. Waiting for your reply! info@hmconcreteplant.com

© 2016 haomei mobile concrete batching plant. All Rights Reserved | Design by concrete mixing plant-Haomei Machinery Equipment Co.,ltd